- Daily & Weekly newsletters

- Buy & download The Bulletin

- Comment on our articles

UGent develops “sponge” to extract CO2 from exhaust gases

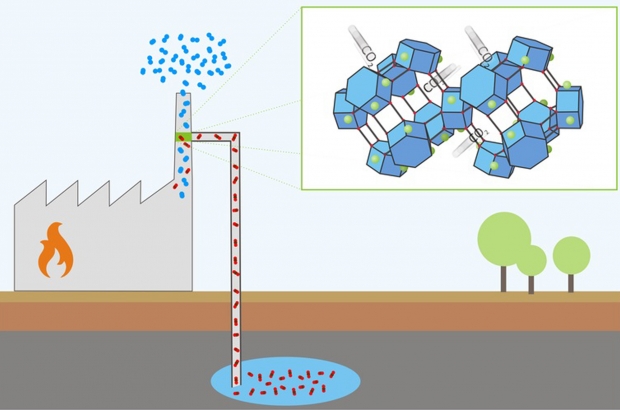

The centre for molecular modelling at Ghent University (UGent) and the University of California in Berkeley have developed a new technology to extract carbon dioxide (CO2) from exhaust gases.

The universities focused on carbon capture and sequestration (CCS), a technology that captures exhaust gases from power plants and stores them underground. The method helps reduce the emission of CO2 in the atmosphere, but the high working cost of the process has always been a problem.

The new technique (pictured) is based on the use of nano-porous materials, which function as a CO2 sponge. The material has pores that are not much bigger than CO2 molecules. When there is contact with exhaust gases, the “sponge” only absorbs CO2.

In conventional CCS, the sponge is then “squeezed out” by heating it, thus removing the CO2. This process requires a lot of energy and is expensive. With the new method, the sponge is submerged in water, which removes the CO2 from the material. The water is then removed by bringing the sponge into contact with the hot exhaust gases.

Through this approach, no energy has to be added for the process and the working cost is reduced. “This breakthrough brings the large-scale application of CCS a step closer,” UGent said in a statement. The research results were published in the magazine Energy & Environmental Science.

Comments

... and about time to!